Table Of Content

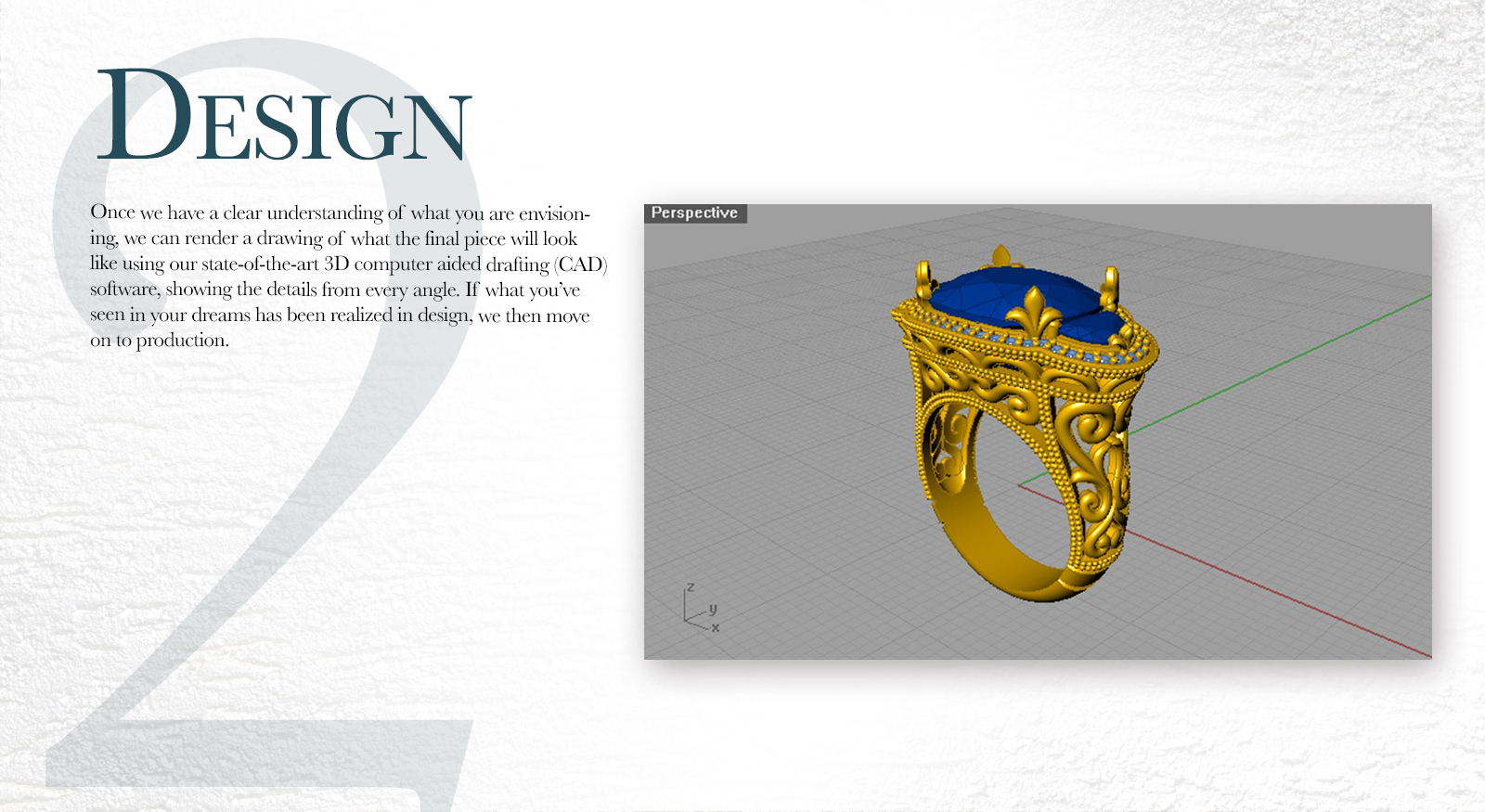

Direct surface modeling is when the desired shape is created from primitive shapes by manipulating surface position and/or adjusting control points of different curves. Depending on the CAD software, we can start our design process with primitives like box, cylinder, sphere, torus, pipe, plane, etc. Wireframe model does not provide the volume information of the various regions of the part. They have been replaced with surface and solid modeling because they are hard to visualize, create uncertainty about design intent, and do not provide a true representation of a product. However, they are still used as a way to create a pictorial view for a 2-D drawing. Computer-aided design (CAD) is a crucial field in product engineering and the industrial sector.

What is CAD? Conclusion

Once you develop the geometric model, you can proceed with following steps like finite element analysis (FEA), rendering, drafting, etc. CAD is used in industrial design to create sleek and functional product designs, integrate with other design tools, and streamline manufacturing processes. With these benefits in mind, it’s easy to see why CAD has become an essential tool in modern design processes. Whether you’re working in architecture, product design, mechanical engineering, or any other industry that uses design, CAD is a powerful tool that can help you create better designs more efficiently. Overall, CAD software provides designers and engineers with precise and efficient tools for creating and manipulating digital designs. With continued innovation and development, CAD applications are expected to become even more powerful and essential in a wide range of industries.

Printing In Space – Top Projects in 2023

Who are the leading innovators in AI-assisted CAD for the oil & gas industry? - Offshore Technology

Who are the leading innovators in AI-assisted CAD for the oil & gas industry?.

Posted: Thu, 04 Jan 2024 08:00:00 GMT [source]

The best results are achieved when both CAD and CAM are used together, as they provide much more control over the entire process from conceptualization through to realization. We’ve already touched on some of the many applications of CAD, but now let’s take a more detailed look at some of the most common and significant uses of CAD software. Price – The best CAD software can be costly – thousands of dollars in some cases. There are a range of benefits that make CAD such a valuable tool across multiple industries. With 3D CAD, engineers can choose from preloaded models like doors and windows or start from scratch by utilizing fill-in parameters.

Best Product Design Software in 2024 (Free & Paid)

The utilization of CAD spans across diverse industries, including architecture, engineering, manufacturing, and construction. Additionally, it finds widespread application in product design, automotive design, and film animation. CAD tools provide designers with the ability to simulate the behavior of designs under different conditions. This feature is particularly useful in engineering and architecture, where designs must meet specific performance criteria. Simulation allows designers to identify potential issues before construction, saving time and resources.

What challenges are associated with adopting CAD technology?

The term “computer-aided design” was coined in 1959 by MIT researcher Douglas T. Ross. As well as expensive paid-for CAD software used by professionals, there are also free programs that are better suited to students and hobbyists. For example, While AutoCAD is the industry leader and is used by professionals across a wide range of sectors, Blender is a high quality free CAD software that is available to anyone. CAD software takes into account how the various materials involved in a project interact, allowing designers to consider every element in a project, from plumbing to electricity. As CAD allows for easy modification, documentation and collaboration, it is a far more precise, efficient and faster method than traditional manual drafting. A decade later, Ivan Sutherland created Sketchpad, which incorporated an innovative graphical user interface.

It is also useful when designing molds and you need to know whether the material in the mold will flow correctly. CAD systems have preset algorithms that have been programmed to increase the accuracy of drawings. They make it possible to identify the starting point, midpoint, and end point of any straight line in the model automatically.

Just In Time (JIT) delivery is a foundational method of construction site logistics and inventory management. JIT involves scheduling and procuring materials to be delivered on site as close to... When Cylwik was in Sundt’s transportation group, he used CAD data to determine the elevations of roads, bridges, and other surfaces. The team connected CAD to equipment in the field to ensure the equipment was performing tasks according to the specs. Cylwik’s use of CAD dates back to his college days at Arizona State University where he majored in design studies.

The height of the item (i.e., thickness or depth) at each place is commonly depicted for objects of this type using a contour map. According to application-specific norms, the CAD output must express information, such as materials, procedures, measurements, and tolerances, just like hand drafting of technical and engineering drawings. The software also considers the interactions between various materials and stakeholders, which is particularly important as more specifics are added to the drawings by subcontractors. This is because of the practical experience offered in a CAD certificate program. In Goodwin’s training program, for example, students gain hands-on practice, designing 2-dimensional and 3-dimensional parts using industry software like Solidworks, Mastercam, and PC-DMIS.

What industries use CAD?

Surfaces can be created using different techniques, and each CAD software has unique methods for creating and working with surfaces. Polygonal modeling is a basic form of surface modeling that produces lower-quality surfaces without precise curvature control. Polygonal modeling creates quick and easy-to-modify surfaces, and most CAD systems use non-uniform rational B-spline (NURBS) mathematics to produce accurate curves. A spline is a curve that uses a series of control points and other mathematical principles to define the location and form of the curve.

In this article, we are going to talk about what CAD is, what benefits and applications of CAD are, and look into the CAD modeling types. Animations and other presentational materials can also be produced using CAD, which can also be used to construct 2D or 3D representations. Detailed instructions on how to make something are delivered through technical drawings. Designs for mechanical engineering and architectural structures can be included in technical drawings using CAD. Developing computer models with geometrical constraints is known as computer-aided design (CAD). These models often provide a three-dimensional representation of a component or a whole system on a computer screen.

BIM (building information modeling) is a 3D model-based process that allows for more efficient design and construction in architecture projects by incorporating intelligent automation and collaboration tools. A program that runs on Microsoft Windows, SolidWorks Premium has powerful 3D design capabilities. While it can be used to create 2D designs, the 3D-related tools are what make it so valuable for mechanical engineers and designers. A computer aided design designer creates digital models and designs using computer software.

Drawings made on a drawing board were replaced with drawing creation on computers, and CAD was initially the term for Computer Aided Drafting. With further development of computers and software, 3D modeling was introduced to the market. This significantly changed the approach to design, and a new term was born, Computer-Aided Design. With these software capabilities, you can also often hear the term CADD – Computer Aided Design and Drafting. In a nutshell, Computer-aided design and Computer-aided drafting terms are used to describe the use of Computer with CAD software for design and drafting applications. The features of this software enable the creation of intricate furniture that is frequently more intricate than specialized furniture design tools.

Every object, line or curve needed to be drawn by hand using rulers, protractors and other drafting tools. Calculations, such as the structural load on a building component, would need to be done manually by an engineer or designer, a very time consuming - and error prone - process. CAD is used in architecture and construction to create detailed architectural plans, generate accurate construction drawings, and facilitate project coordination and communication. Designers and engineers use CAD solutions to create and optimize vehicle components, conduct crash simulations, and improve performance. Today, CAD has evolved into a sophisticated and powerful tool with advanced features such as parametric modeling, cloud-based collaboration, and virtual reality integration.

For example, you can use a computer keyboard to type the predetermined length of lines and the exact angles of polygons in order to minimize errors. Globalization has made it possible for people from different parts of the world to bring their minds together to accomplish mutually beneficial projects. Multinational companies have employees from different countries and time zones carrying out joint tasks and contributing to the development of collaborative projects.

NIST Engineer Offers a Way to Realize the Digital Thread in Manufacturing NIST - NIST

NIST Engineer Offers a Way to Realize the Digital Thread in Manufacturing NIST.

Posted: Thu, 01 Jun 2023 07:00:00 GMT [source]

3D CAD systems initially only modeled arcs and lines and were referred to as 3D Wire-frame Models. They presented a skeletal representation of the finished product and displayed all internal components of the system. However, as computers became smaller and more affordable, people began using them in their homes, offices, and universities leading to a boom in the number of CAD users all over the world. Hanratty upgraded ADAM over time, enabling it to run on 16-bit, and later 32-bit computers. With a name change to AD-2000 along with more machining and surfacing capabilities, the program became more and more of a success.

There are several things to look into when you are getting started with CAD software but we will only list a few of them here to get you off on the right track. The pressure sensitivity simply indicates how much you can vary the thickness or opacity of a line by the amount of pressure you put on it. It is designed to imitate the effect of using a paintbrush or soft pencil where the more pressure you use, the thicker the lines. CAD users who work a lot on the move are big fans of Bluetooth mice because they are wireless, compact, and easy to travel with.

No comments:

Post a Comment